High precision 7215 Angular contact bearing

The angular contact bearing 7215 is a kind of rolling-element bearing that helps each radial and axial (thrust) masses and operates at excessive speeds. This kind of bearing consists of an internal and outer ring with raceways that are designed at an perspective to the bearing axis, and the balls or rollers make contact with the internal and outer races at a particular point.

High precision 7215 Angular contact bearing

7205AC is angular contact bearing with nylon cage. There are also steel and brass cage.

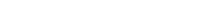

The angular contact bearing 7215 has a bore size of 75mm, an outer diameter of 130mm, and a width of 25mm. It is commonly made of chrome steel or stainless steel and is designed to withstand high-speed and high-load conditions. It is commonly used in machine tools, motors, and pumps.

During installation or maintenance, it is important to follow manufacturer guidelines, use appropriate tools, and ensure proper lubrication to prolong its lifespan and ensure optimal performance. Regular inspections and replacement of worn or damaged bearings will help to prevent equipment failure and downtime.

Diameter

75 mm | Bore diameter |

130 mm | Outside diameter |

25 mm | Width |

≈96.3 mm | Shoulder diameter of inner ring (large side face) |

≈85.25 mm | Shoulder diameter of inner ring (small side face) |

≈110.1 mm | Shoulder diameter of outer ring (large side face) |

56 mm | Distance side face to pressure point |

min.1.5 mm | Chamfer dimension |

min.1 mm | Chamfer dimension |

Discription

High quality steel: ultra-clean steel makes bearing extends life up to 80%. |

Llubrication technology: Best lubrication grease extend products life and performance. |

High-grade balls: quiet and smooth operation even in the case of high-speed. It also can maintain smooth operation. |

Super finished raceway: special grinder, to reduce the occurrence of noise, improve the distribution of lubricating oil and life. |

Contact Angle: 15,25,30 and 40 degrees. |

Good seals resistance to pollution in harsh environment. |

Cage: reference application range is nylon, steel, brass cage components etc. |

Quality assurance: 100% test carefully to ensure the quality of the whole product. |

Faqs:

What is a high-precision 7215 angular contact bearing?

High precision 7215 angular contact bearing is a bearing designed to handle radial and axial loads. It uses ball bearings arranged in a single row with a contact angle of 40°. This enables it to achieve high precision and speed, making it ideal for use in applications where accuracy and reliability are critical.

What are the main features of high precision 7215 angular contact bearings?

Key features of the High Precision 7215 Angular Contact Bearing include its high speed capability, ability to handle radial and axial loads, use of single row ball bearings, and 40° contact angle. It can also be designed with seals, shields or other protective features to prevent contamination and extend its life.

What are some common applications for High Precision 7215 Angular Contact Bearings?

High precision 7215 angular contact bearings can be used in a variety of applications requiring high precision and high speed. Some common applications include machine tools, robotics, aerospace equipment, and medical equipment. It can also be used in automobiles, agricultural and industrial machinery, and other applications.

What are the benefits of using high precision 7215 angular contact bearings?

Benefits of using high precision 7215 angular contact bearings include their high precision and high speed capability, ability to handle radial and axial loads, and long service life. By choosing high-quality, reliable bearings, you can ensure your equipment operates with greater efficiency, reliability and safety.

How do I choose the right high precision 7215 angular contact bearing for my application?

To select the appropriate high precision 7215 angular contact bearing for your application, consider factors such as speed requirements, load capacity, operating environment and desired service life. Consulting with the bearing supplier or manufacturer can also help you determine the best option for your specific needs.

| High quality steel: ultra-clean steel makes bearing extends life up to 80%. |

| Llubrication technology: Best lubrication grease extend products life and performance. |

| High-grade balls: quiet and smooth operation even in the case of high-speed. It also can maintain smooth operation. |

| Super finished raceway: special grinder, to reduce the occurrence of noise, improve the distribution of lubricating oil and life. |

| Contact Angle: 15,25,30 and 40 degrees. |

| Good seals resistance to pollution in harsh environment. |

| Cage: reference application range is nylon, steel, brass cage components etc. |

| Quality assurance: 100% test carefully to ensure the quality of the whole product. |

Related Products

Submitted successfully

We will contact you as soon as possible