Self lubrication graphite copper based alloy oil-free sleeve bearing SF-1

1.Strict material selection

SF-1 composite sleeve is based on carbon steel as the matrix outside copper plating, inner sintered composite wear-resistant material PTFE (polytetrafluoroethylene), with no lubricating oil function

High tensile brass,long service life,not easy to corrosion and wear,high load resistance,suitable for high-demand occasions

Strict selection of graphite,using turning graphite,oil absorption rate is high,increse the lubrication effect of products

2.Long life high precision

High temperature resistance,high precision,strong hardness and certain toughness,long life

3.Good speed,low noise

Operation speed uniform,and mechanical coordination work,improve efficiency

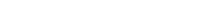

SF-1 metal composite oil-free lubrication lubrication bearing SF-1

Bore diameter | Outside diameter | Width | Bearing material | Bearing load direction | Bearing mechanism | Type of lubrication |

| 55mm | 60mm | 30mm | Copper-based alloy | Radical bearing | Solid friction | Solid lubrication |

Oil-free or less lubricated, can be used with no or little maintenance.

Good wear resistance, small friction coefficient, long service life.

With appropriate elastoplasticity, the stress can be distributed on a wide contact surface to improve the bearing capacity.

The static and dynamic friction coefficient is similar to ensure the working accuracy of the machine.

can make machinery reduce vibration, reduce noise, prevent pollution, improve working conditions.

In the running process can form a transfer film, play a role in protecting the grinding shaft.

The hardness of the grinding shaft is low, thus reducing the difficulty of processing related parts. Thin wall structure, light weight, can reduce the mechanical volume. 9 steel back can be electroplated a variety of metals, can be used in corrosive media; It has been widely used in sliding parts of various machinery.

Related Products

Submitted successfully

We will contact you as soon as possible