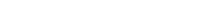

self lubrication graphite copper sleeve bearing JDB1635

1.Strict material selection

SF-1 composite sleeve is based on carbon steel as the matrix outside copper plating, inner sintered composite wear-resistant material PTFE (polytetrafluoroethylene), with no lubricating oil function

High tensile brass,long service life,not easy to corrosion and wear,high load resistance,suitable for high-demand occasions

Strict selection of graphite,using turning graphite,oil absorption rate is high,increse the lubrication effect of products

2.Long life high precision

High temperature resistance,high precision,strong hardness and certain toughness,long life

3.Good speed,low noise

Operation speed uniform,and mechanical coordination work,improve efficiency

Self lubrication graphite copper sleeve bearing JDB1635

1. the mixture of PPFE and fiber is zero.01~zero.03mm, which can shape an awesome switch movie to guard the grinding shaft and provide the self-lubricating overall performance of the bearing.

2. the copper powder layer is 0.20~0.30mm, which has the top bearing capacity and put-on resistance, and true thermal conductivity can transfer the warmth generated in the course of the operation of the bearing in time. the composite cloth can penetrate into the gaps of the copper powder balls, improving the bonding power.

3. low-carbon steel, which presents good load-bearing performance and heat switch features. the products have been widely utilized in sliding components of various equipment, which include printing machines, elevators, fabric machines, tobacco machines, fitness systems, hydraulic vehicles, micro-motors, solenoid valves, cars, motorcycles, and so forth.

Bore diameter | Outside diameter | Load direction | Bearing mechanism | Lubricant | Oil lubrication method | Lubrication state | Axial tile material | Purpose | Usage characteristics |

| 40mm | 50mm | Both are acceptable | Solid friction | Solid lubrication | Oil drip lubrication | Fluid film lubrication | Copper | Construction machinery | Low temperature |

Related Products

Submitted successfully

We will contact you as soon as possible