Guide rail sliding block bearing HGH15CA

HGH15CA guide rail has high positioning accuracy and less wear which can maintain accuracy for a long time.

It is suitable for high-speed movement and greatly reduce the drive horsepower required by the machine,

It can withstand the load in the left and right directions at the same time, easy assembly and interchangeability.

HG series is a four-row single-arc tooth contact linear guide, and integrates the optimized structure of the overweight load precision linear guide, compared with other linear guides to improve the load and rigidity; With four directions and other load features, and automatic aligning function, can absorb the mounting surface assembly error, get high precision demands. The concept of high speed, high load, high rigidity and high precision has become the trend of the future development of industrial products around the world.

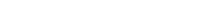

Dimensions OF HGH15CA

| H | H1 | N | W | B | B1 | C | L1 | L | K1 | K2 | G | Mxl | T | H2 | H3 | Wr | Hr | D | h | d | P | E |

| 28 | 4.3 | 9.5 | 34 | 26 | 4 | 26 | 39.4 | 61.4 | 10 | 4.85 | 5.3 | M4*5 | 6 | 7.95 | 7.7 | 15 | 15 | 7.5 | 5.3 | 4.5 | 60 | 20 |

| C | Cor |

| 11.38 | 16.97 |

WEIGHT

0.18KG BLOCK

1.45KG RAIL/M

Features:

(1) Automatic aligning ability

The DF(45°-45°) combination from the arc groove, during installation, through the elastic deformation of the steel ball and the transfer of the contact point, even if the mounting surface is somewhat deviated, it can be absorbed by the HG slider, resulting in the effect of automatic aligning ability and obtain high precision and stable smooth movement.

(2) Interchangeability

Due to the strict control of the manufacturing accuracy, the linear guide size can be maintained within a certain level, and the slider has a reholder design to prevent the steel ball from falling off, so some series of precision is interchangeable, customers can order the guide rail or slide, can also store the guide rail and slide separately to reduce storage space.

(3) High rigidity in all directions

The use of four rows of circular grooves, with four rows of steel balls such as 45 degrees of contact Angle, so that the steel ball to achieve the ideal two-point contact structure, can withstand from the upper and lower and left and right direction of the load; If necessary, prepressure can be applied to improve rigidity.

| Item(CPO/XPO/ARO) | ID (mm) | OD(mm) | T(mm) |

| KC040 | 101.6 | 120.65 | 9.525 |

| KC042 | 107.95 | 127 | 9.525 |

| KC045 | 114.3 | 133.35 | 9.525 |

| KC047 | 120.65 | 139.7 | 9.525 |

| KC050 | 127 | 146.05 | 9.525 |

| KC055 | 139.7 | 158.75 | 9.525 |

| KC060 | 152.4 | 171.45 | 9.525 |

| KC065 | 165.1 | 184.15 | 9.525 |

| KC070 | 177.8 | 196.85 | 9.525 |

| KC075 | 190.5 | 209.55 | 9.525 |

| KC080 | 203.2 | 222.25 | 9.525 |

| KC090 | 228.6 | 247.65 | 9.525 |

| KC100 | 254 | 273.05 | 9.525 |

| KC110 | 279.4 | 298.45 | 9.525 |

| KC120 | 304.8 | 323.85 | 9.525 |

| KC140 | 355.6 | 374.65 | 9.525 |

| KC160 | 406.4 | 425.45 | 9.525 |

| KC180 | 457.2 | 476.25 | 9.525 |

| KC200 | 508 | 527.05 | 9.525 |

| KC250 | 635 | 654.05 | 9.525 |

| KC300 | 762 | 781.05 | 9.525 |

Related Products

Submitted successfully

We will contact you as soon as possible