Excavator walking angular contact bearing BA180-4WSA

1.Selected materials

National standard bearing steel is preferred with good quality and strong corrosion resistance.

2.High degree accuracy

Automatic CNC machine tool processing, reduce the error of manual assembly, achieve unity.

3.Long service life

Excellent material selection, coupled with scientific industrial design, avoid the trouble of repeated disassembly and assembly

4.Strong stability

High assembly of domestic precision heart, integration and optimization of structural design

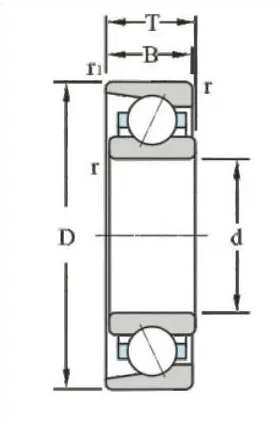

Excavator walking angular contact bearing BA180-4WSA

Bore diameter | Outside diameter | Thickness | Weight | Number of scrolling columns | Type of raceway | Bearing material | Rolling body | Angle | Purpose |

| 222 | 273 | 36 | 1.35 | List as an independent unit | Deep groove raceway | GCr15 | Steel ball | S special angle design | Construction machinery |

The installation and disassembly method of excavator bearings should be based on the structure, size and the nature of the coordination with excavator bearing components. The pressure of installation and disassembly should be directly added to the end face of the tight fitting excavator bearing, and the pressure can not be transferred through the excavator bearing rolling body, because it will cause indentation on the working surface of the excavator bearing, affect the normal work of the excavator bearing, and even damage the excavator bearing. The cage, sealing ring, dust cover and other parts of the excavator bearing are easy to deform, and the pressure of installing or disassembling the excavator bearing cannot be added to these parts.

Related Products

Submitted successfully

We will contact you as soon as possible